The environmental regulations already in the process of implementation and those still under development represent a radical shift towards lowering and ultimately removing carbon emissions from the industry. Shipowners must shape their business strategies to reflect tightening environmental controls in the coming decade and beyond. However, the focus of all these regulations appears to relate more to the atmospheric related emissions and less to emissions related to ocean-waters pollution. ABS intends to re-visit this through its R&D facilities in the ABS Athens office.

Most ocean-going ships operate with oil-lubricated stern tubes and use lubricating oils in many applications in both on-deck machinery and in-water (submerged) machinery. The issue of oil leakage from stern tubes, once considered a part of the normal operational consumption of oil, has become a greater concern and is now considered to be oil pollution, with associated legal consequences. Greater focus on stern tube leakage and the release of other types of lubricants used in marine shipping operations have led to a need to evaluate alternatives to these oils and ways to monitor and prevent discharge of lubricants during ship operations in ports and at sea. Recent sustainability technologies have not addressed the issue of water pollution due to oil leakage from the aft stern tube bearings of vessels. Environmental regulations have put a greater focus on atmospheric pollution and pertinent emissions.

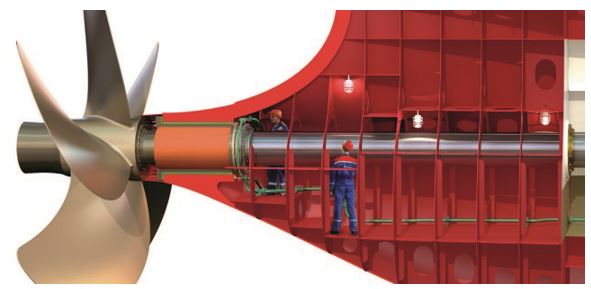

ABS together with Thordon Bearings Inc, SDARI in China and NTUA have embarked on a study to investigate a significant design intervention in the internals of the aft part of a vessel over typical commercial vessel designs. The joint consortium revisited an existing container vessel design and made a number of design interventions including but not limited to installation of sea water-lubricated bearings.

The installation of aft water lubricating bearings is not something new; many naval and commercial vessels have already successfully installed water lubricated bearings using seawater as the lubricant. However, this design proposal is novel in that it involves removing the sterntube casting itself, substantially decreasing the shaft line length, adding a torsional vibration damper to eliminate the Barred Speed Range, and finally the creation of an Irregularly Shaped Chamber behind the bulkhead of the engine room. This chamber provides several benefits to the operational inspection of the shaft line and bearings throughout the life of the vessel. Therefore, in addition to the zero-pollution risk and the lack of required oil changes, there is now the innovative technical advantage of the Irregularly Shaped Chamber, which provides human access for inspection and even bearing replacement from the interior of the vessel. This means that a bearing replacement project or bearing and shaft line inspection activity would no longer require drydocking or shaft removal, nor propeller removal or realignment using laser sighting. Simply put, a 2-week realignment job in a dry-dock costing an average of $100k USD can now take place in only one day and afloat. This novel design proposal complies with all classification society rules and regulations, such as those governing torsio-axial vibration, shaft alignment, and structural integrity requirements. Shaft line optimization considering the wear down rates of the water lubricated bearing ensure longevity of the system.

The ABS TCM-W Notation can be applied in this case, giving the same benefits as the traditional oil lubricated bearings arrangements, meaning a 15-year maximum inspection interval. To best describe this proposed design concept using the latest technology facilities, a real sized 3-dimensional CAD file has been processed to provide a virtual reality guided tour through the shortened engine room space and most importantly inside the newly invented Irregularly Shaped Chamber. Video animation demonstrating the bearing replacement process when the vessel is afloat is also provided to offer greater detail of this concept.

Chris Leontopoulos, PhD, MBA, CEng, FIMechE Director, Global Ship Systems Centre American Bureau of Shipping

Latest News

Capital Link Forum Highlights Greece’s Economic Resurgence; Honors BoG Gov Stournaras

Capital Link Hellenic Leadership Award recipient, Bank of Greece Gov. Yannis Stournaras, an ex-FinMin, was lauded for his pivotal role during Greece’s economic recovery

Tourist Spending in Greece Up by 14%, Visa Card Analysis Shows

Greece’s capital Athens emerged as the most popular destination, recording a 17% increase in transactions with Visa cards, surpassing even the cosmopolitan island of Mykonos.

Inflation in Greece Unchanged at 2.4% in Nov. 2024

The general consumer price index (CPI) posted a 0.4% decrease in November compared to the previous month

2024 Christmas Holidays: Extended Shop Hours Schedule

The 2024 Christmas Holidays extended shop hours schedule commences on Thursday, December 12 and runs until the end of the year.

ELSTAT: Seasonally Adjusted Unemployment Down in October

The number of employed individuals reached 4,284,694, an increase of 67,723 compared to October 2023 (+1.6%) and 22,002 compared to September 2024 (+0.5%).

Greek PM’s Chief Economic Adviser Resigns

In the post on his Facebook page, Patelis did not disclose the reasons that led him to step down.

“Masdar Invests in the people of Greece and in the vision of TERNA ENERGY”

Four messages from the CEO of Masdar, the Arab renewable energy giant, after its acquisition of 70% of TERNA ENERGY

Lloyd’s List Greek Shipping Awards 2024: Honors for leading companies and personalities in the Greek shipping sector

20 awards presented at the 21st annual Lloyd's List Greek Shipping Awards

Syria’s Bashar al-Assad, His family Granted Asylum by Russia

Reuters also reported that a deal has been struck to ensure the safety of Russian military bases in the war-ravaged country

Greece to Introduce Artificial Intelligence into Its Education System

Currently, Greece is taking its first steps to bring AI into classrooms through the AI4edu program, which is being co-funded by the European Union

![Χειμερινή εξοχική κατοικία: Οι Ελληνες γυρνούν την πλάτη παρά την πτώση των τιμών [γραφήματα]](https://www.ot.gr/wp-content/uploads/2024/12/Capture-19-90x90.jpg)

Αριθμός Πιστοποίησης Μ.Η.Τ.232433

Αριθμός Πιστοποίησης Μ.Η.Τ.232433